The world of CNC (Computer Numerical Control) machining is constantly evolving, with advancements that offer greater precision, efficiency, and flexibility for machinists and hobbyists alike. One of the most powerful tools in the CNC realm is the Mach4 CNC controller, a versatile software that controls various types of machinery and optimizes workflow. Alongside Mach4, components like PoKeys devices, specialized Mach4 motion controllers, and advanced probing techniques play crucial roles in maximizing the performance of CNC machines.

In this guide, we will explore the core components that enhance CNC operations, starting with an in-depth look at the Mach4 CNC controller. We’ll delve into the PoKeys tutorial to understand how these versatile devices can interface with CNC machines to enhance functionality. Then, we’ll discuss the importance of the Mach4 motion controller in achieving smooth, precise movements. Finally, we’ll examine Mach4 probing techniques that ensure accuracy in machining processes. By the end of this article, you’ll have a comprehensive understanding of how these elements interconnect to create a powerful CNC setup, optimized for any machining task.

Understanding the Mach4 CNC Controller

The Mach4 CNC controller is a powerful and flexible software solution designed to manage and optimize CNC machinery. It serves as the brain of the CNC machine, interpreting G-code files and converting them into precise motions that control various types of machines, from mills and lathes to routers and plasma cutters. Mach4 is highly customizable, allowing users to tailor the software to their specific needs, whether for industrial applications or hobbyist projects.

One of the standout features of the Mach4 CNC controller is its modular architecture. This modularity means that different components of the software can be updated or modified independently, making it easier to customize and upgrade over time. Users can add plugins and scripts to extend the software’s functionality, enabling them to control unique hardware setups or perform specialized tasks. This flexibility is a significant improvement over earlier versions, which were more rigid and limited in their adaptability.

Another key advantage of the Mach4 CNC controller is its improved motion control capabilities. Unlike its predecessor, Mach3, Mach4 was designed with multi-core processors in mind, allowing it to handle more complex computations and provide smoother, more precise control over machine movements. This results in better surface finishes, reduced wear on machine components, and increased overall efficiency. Mach4’s motion control engine can handle up to six axes simultaneously, making it ideal for advanced CNC machines that require precise, synchronized movement.

In summary, the Mach4 CNC controller is a robust, versatile software solution that offers significant improvements in performance and customization over previous versions. Its ability to adapt to a wide range of CNC applications makes it an essential tool for anyone looking to optimize their CNC machining processes. Whether you’re a professional machinist or a DIY enthusiast, understanding how to leverage the capabilities of Mach4 can greatly enhance your machining experience.

PoKeys Tutorial: Enhancing Your CNC Setup

Integrating additional hardware like PoKeys devices can significantly enhance the functionality and flexibility of a CNC machine controlled by the Mach4 CNC controller. PoKeys is a versatile, user-friendly device that serves as an interface between the CNC machine and the computer running the Mach4 software. It offers a wide range of input and output options, allowing users to add custom controls, sensors, and other peripherals to their CNC setup.

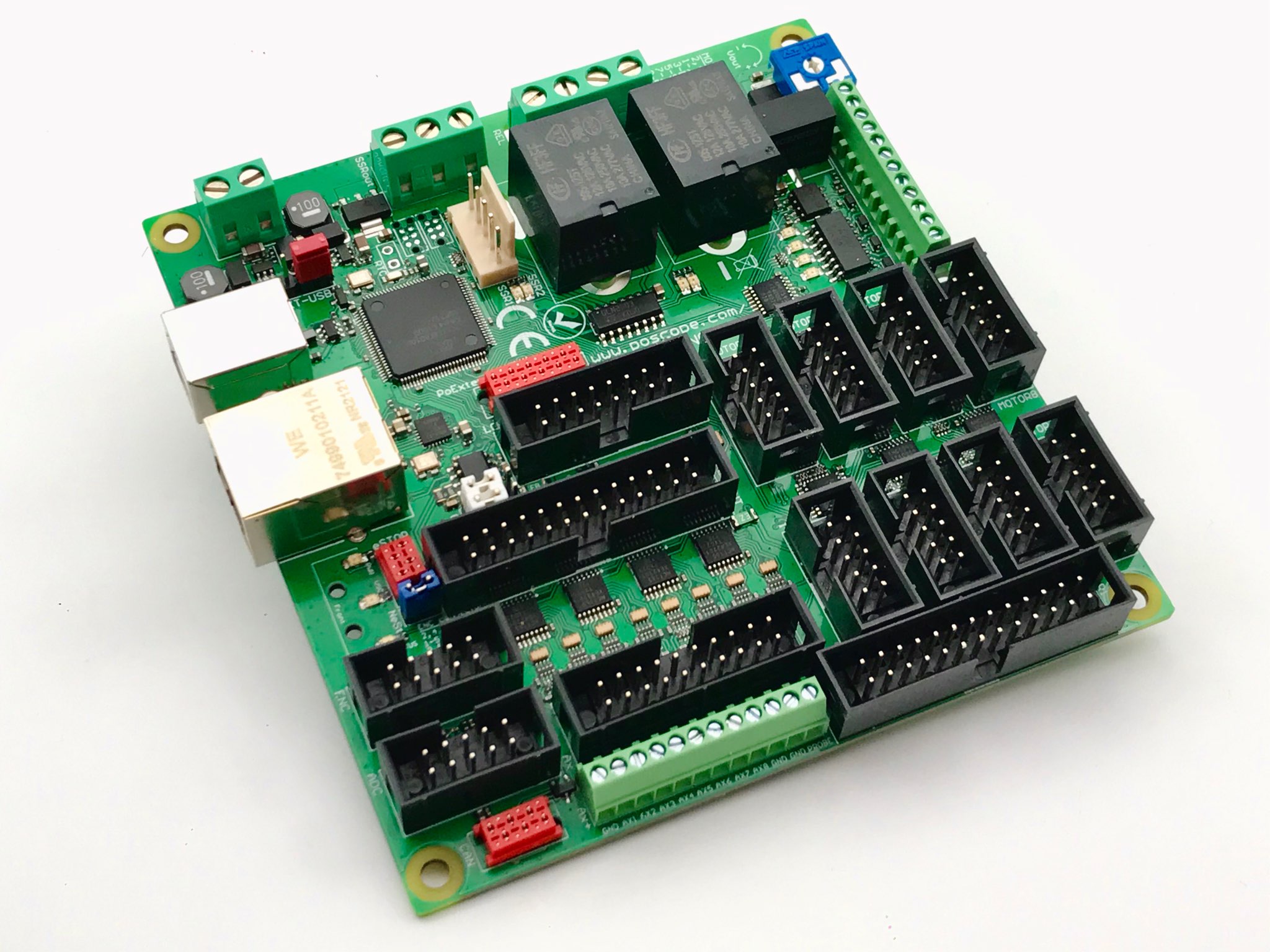

In this PoKeys tutorial, we will explore how to set up and use PoKeys devices with Mach4, highlighting the key features and benefits of this powerful interface. To get started, you’ll need a PoKeys device, such as the PoKeys57CNC, which is specifically designed for CNC applications. This device connects to your computer via USB or Ethernet, providing a fast and reliable communication link.

The first step in using PoKeys with Mach4 is to install the appropriate drivers and software. Once installed, the PoKeys device can be configured through its user-friendly interface, allowing you to assign various functions to the inputs and outputs. This might include setting up buttons for jogging the machine, controlling spindle speed, or activating coolant systems. The versatility of PoKeys devices means you can tailor your CNC machine to your exact requirements, enhancing productivity and ease of use.

Another significant advantage of using PoKeys devices is their ability to handle real-time data exchange between the CNC machine and the Mach4 software. This ensures that commands are executed promptly, reducing lag and improving the overall responsiveness of the machine. Additionally, PoKeys devices support various communication protocols, making them compatible with a wide range of CNC hardware and accessories.

In conclusion, PoKeys devices provide a powerful and flexible way to expand the capabilities of your CNC machine when used with the Mach4 CNC controller. By following this PoKeys tutorial and exploring the various configuration options, you can customize your setup to better meet your specific machining needs. Whether you’re adding new controls, sensors, or other peripherals, PoKeys devices offer an easy and efficient way to enhance your CNC experience.

The Role of the Mach4 Motion Controller in Precision Machining

When it comes to precision machining, the Mach4 motion controller is an essential component that plays a critical role in the accuracy and efficiency of CNC operations. The motion controller acts as the interface between the Mach4 CNC controller software and the physical machinery, translating the digital commands into precise physical movements. Understanding the significance of the Mach4 motion controller can help you optimize your CNC setup for superior performance.

The Mach4 motion controller offers advanced motion control capabilities that are essential for high-precision tasks. It manages the coordination of multiple axes, ensuring that movements are smooth and synchronized. This is crucial for complex machining operations that require precise alignment and positioning. For example, in a multi-axis milling machine, the motion controller ensures that the tool paths are accurately followed, reducing errors and improving the quality of the finished product.

One of the key features of the Mach4 motion controller is its ability to handle real-time motion control. Unlike older systems that might suffer from lag or latency, the Mach4 motion controller processes commands in real time, providing immediate feedback and adjustments. This real-time processing is particularly beneficial for high-speed machining and applications requiring rapid changes in direction or speed.

Additionally, the Mach4 motion controller supports a variety of advanced motion profiles, including linear, circular, and helical interpolations. This versatility allows for more complex and detailed machining operations, such as intricate patterns or contours. By providing precise control over these motion profiles, the Mach4 motion controller ensures that your CNC machine can handle a wide range of tasks with high accuracy.

In summary, the Mach4 motion controller is a vital component in achieving high-precision machining. Its ability to handle real-time processing, manage multiple axes, and support various motion profiles makes it an indispensable tool for both industrial and hobbyist CNC applications. By leveraging the capabilities of the Mach4 motion controller, you can enhance the performance of your CNC machine and achieve superior results in your machining projects.

Mastering Mach4 Probing Techniques for Enhanced Accuracy

In the realm of CNC machining, Mach4 probing techniques are pivotal for achieving high levels of accuracy and repeatability. Probing involves using a touch probe to measure or inspect parts and features during the machining process. This capability is essential for ensuring that parts meet exact specifications and for optimizing the setup of CNC machines. Understanding and implementing Mach4 probing techniques can significantly improve your machining results.

Mach4 probing is integrated into the Mach4 CNC controller software, providing users with powerful tools to automate and enhance measurement processes. One of the primary functions of Mach4 probing is to perform automatic part measurements. By using a touch probe, Mach4 can automatically detect the edges, surfaces, and features of a workpiece, allowing for precise alignment and positioning. This is particularly useful for creating complex parts where exact measurements are critical.

Another advantage of Mach4 probing is its ability to perform automatic tool length and diameter measurements. This feature is crucial for maintaining accuracy throughout the machining process. By regularly measuring tool lengths and diameters, Mach4 ensures that the tool offsets are always correct, reducing the likelihood of errors and improving the consistency of the finished parts.

Mach4 probing also supports advanced probing techniques, such as differential probing and auto-correction. Differential probing involves measuring two points on a surface to detect variations in height or angle, which can be used to correct alignment issues or compensate for material inconsistencies. Auto-correction adjusts the machine’s movements based on probing data, allowing for real-time adjustments and enhancing the overall precision of the machining process.

Additionally, Mach4 probing techniques can be used to streamline the setup of CNC machines. By using probing to automatically establish reference points and work offsets, machinists can reduce setup times and minimize the risk of errors. This automated approach not only speeds up the process but also ensures that the machine is correctly calibrated for each new job.

In summary, mastering Mach4 probing techniques is essential for achieving high levels of accuracy and efficiency in CNC machining. By leveraging the capabilities of Mach4 for automatic measurements, tool checks, and real-time adjustments, you can significantly enhance the precision and reliability of your machining operations. Whether you’re performing complex measurements or streamlining machine setup, Mach4 probing provides the tools you need to achieve superior results.

Conclusion

In this comprehensive guide, we’ve explored the integral components that elevate CNC machining to new levels of precision and efficiency: the Mach4 CNC controller, PoKeys devices, the Mach4 motion controller, and Mach4 probing techniques. Each element plays a vital role in ensuring that your CNC machine operates smoothly and accurately, providing you with the tools needed for both complex industrial tasks and intricate hobby projects.

The Mach4 CNC controller is the cornerstone of this setup, offering advanced software capabilities that translate digital commands into precise machine movements. Its modular design allows for extensive customization, making it adaptable to various CNC applications. Complementing this is the PoKeys device, which enhances the flexibility and functionality of the CNC system by providing a versatile interface for additional controls and peripherals.

The Mach4 motion controller further refines the precision of your machining operations. Its real-time processing and multi-axis management ensure smooth and accurate movements, crucial for high-quality results. Coupled with Mach4 probing techniques, which automate part measurements and tool checks, you can achieve exceptional accuracy and consistency in your machining processes. Probing not only simplifies setup but also ensures that each part meets exact specifications.

By understanding and integrating these components, you can optimize your CNC setup for superior performance. Whether you are setting up a new CNC machine or looking to enhance an existing one, leveraging the Mach4 CNC controller, PoKeys, Mach4 motion controller, and Mach4 probing techniques will significantly improve the efficiency and precision of your operations.

In summary, mastering these technologies allows you to harness the full potential of your CNC machine, leading to better results, reduced errors, and increased productivity. Embracing these tools and techniques will pave the way for successful and precise CNC machining, helping you achieve your project goals with confidence and ease.